Kutembenuka Kumodzi

Potengera lamba wa conveyor kuti atembenuke.gawo la arc la conveyor lidzalumikizana ndi chotengera chowongoka ndipo malekezero onse a gawo la arc ayenera kuwongolera mowongoka, ndiyeno chotengeracho chidzagwira ntchito bwino.

Utali wamkati wamkati umafunikira nthawi zosachepera 2.2 m'lifupi mwake lamba wonyamulira.

STL1 ≧ 1.5 XW kapena STL1 ≧ 1000mm

Kutembenuka kamodzi sikungopitirira 90 °;iyenera kumvera malire a kutembenuka kwa radius ndikupanga mapangidwe kuchokera ku 15 °, 30 °, 45 °, 60 °, 75 °, 90 °, .... mpaka 360 °.

Seri Kutembenuza

Potengera lamba wa conveyor kuti atembenuke.gawo la arc la conveyor lidzalumikizana ndi chotengera chowongoka ndipo malekezero onse a gawo la arc ayenera kuwongolera mowongoka, ndiyeno chotengeracho chidzagwira ntchito bwino.Kutalika kwa ntchito yowongoka kumafuna 2times m'lifupi mwa lamba wa conveyor.Pakutembenuka kwa serial, chonde musapangire matembenuzidwe opitilira 4.

Utali wamkati wamkati umafunikira nthawi zosachepera 2.2 m'lifupi mwake lamba wonyamulira.

STL1 ≧ 1.5 XW kapena STL1 ≧ 1000mm

STL2 ≧ 2 XW kapena STL2 ≧ 1500mm

Zolemba

Chotengeracho chikagwira ntchito, zimakhala zosavuta kupanga maphokoso osazolowereka chifukwa cha kuyimitsidwa ndikugwedezeka.Mapeto a lamba osagwira ntchito sakanatha kusuntha mpaka patakhala kulimba kokwanira kuti muthane ndi mkangano pakati pa lamba ndi njira yonyamula.Phokosoli limatha kutha potengera mafuta kapena sopo madzi kuti azipaka njanji ndi zobvala.

Malamba otembenuza a HONGSBELT, amatha kugwiritsidwa ntchito pamalo amvula omwe ali ndi kutentha kwakukulu, monga nthunzi yomwe kutentha kwake ndi 95 ° C.Tikukulimbikitsani kuti utali wozungulira wamkati ukhale wopitilira 3 kuchulukitsa kwa lamba, ndipo ngodya yokhotakhota imodzi kapena yosalekeza isapitirire 180°.Tili ndi mapangidwe enieni ambiri komanso zokumana nazo zomwe munganene;chonde funsani ndi dipatimenti yathu yaukadaulo kapena mabungwe am'deralo.

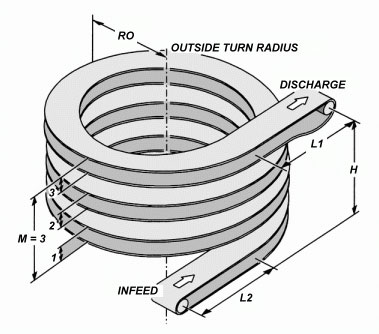

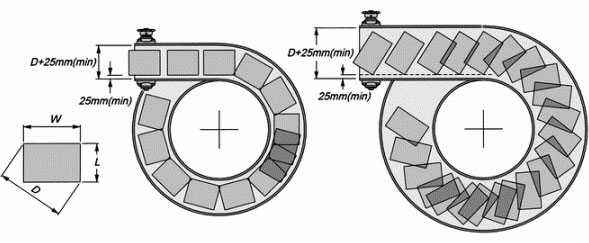

Spiral Conveyor

Pamene mtundu wobwerera wozungulira wozungulira womwe lamba munjira yobwereza ukugwira ntchito ndi njira yonyamulira koma molunjika ukupangidwa mokhotakhota mozungulira ndikugwiritsiridwa ntchito mbali imodzi, upanga mawonekedwe ngati mapindikira ozungulira.Pamalekezero onse a matembenuzidwe ozungulira amafunikiranso kuti aziwongolera mowongoka, ndiyeno zimagwira ntchito.Kutalika kochepa kowongoka kuyenera kukhala kosachepera 1.5 nthawi lamba m'lifupi mwa conveyor, ndipo sakanakhoza wamfupi kuposa 1000mm.

Mkati mwa utali wozungulira wa conveyor wozungulira amazungulira mu madigiri 360;tcherani khutu ku kuchuluka kwa zigawo zosapitirira zigawo zitatu, zimatanthauzanso kuti mbali zonse zozungulira za conveyor zozungulira sizingadutse madigiri 1080.

Zolemba za Spiral Conveyor

Kwa malamba otembenuza a HONGSBELTserial, ngati utali wamkati udutsa nthawi 2.5 m'lifupi mwake lamba, umapanga phokoso lachilendo chifukwa cha zochitika za kupuma ndi kugwedezeka.Mapeto a lamba osagwira ntchito sakanatha kusuntha mpaka patakhala kulimba kokwanira kuti muthane ndi mkangano pakati pa lamba ndi njira yonyamula.Phokosoli limatha kutha potengera mafuta kapena sopo madzi kuti azipaka njanji ndi zobvala.

Fomula Yowerengera ya Kunja kwa Radius ya Spiral Conveyor

Chitsanzo m'munsimu ndi njira yowerengera yakunja/mkati mwa radius ya spiral conveyor belt system.

FORMULA:

Utali wa lamba wotumizira = 2B+ (m'mimba mwake wa sprocket x 3.1416)

A = D × 3.1416 × P (X)

B = ( √ H2 + A2 ) + L1 + L2, B = A / Cos DEG.kapena B = H / Tan DEG.

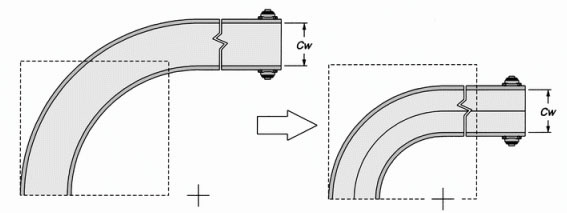

Chepetsani Mkati mwa Radiyo

Pali zoletsa zingapo mkati mwa malamba otembenuza a HONGSBELT.Popanga ndi kupanga malamba otembenuza, vuto la danga la fakitale lidzakumana nthawi zonse.Fakitale siyitha kutengera chotengera chachikulu;m'pofunika kuchepetsa utali wamkati wa lamba.Itha kukhala ndi mizere iwiri ya malamba kapena mizere yambiri yamapangidwe a malamba pagawo lotembenuka kuti ilowe m'malo mwa lamba umodzi, kuti muthane ndi vuto lakutali kwambiri mkati.Komabe, kamangidwe kameneka kakhoza kuchititsa kuti lamba wakunja azithamanga kwambiri kuposa lamba wamkati.Chonde samalani ngati izi zingakhudze mphamvu ya makina otumizira kapena ayi.

Design Chitsanzo

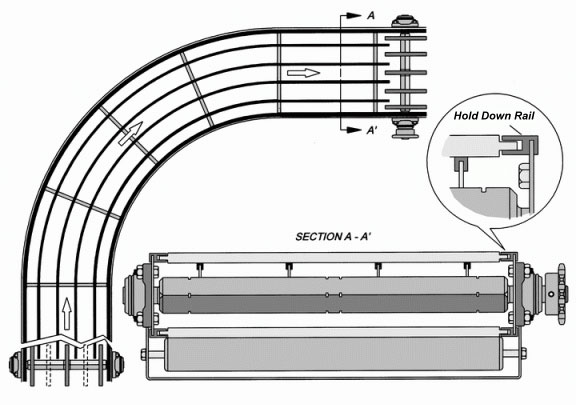

Chitsanzo cha Hold Down Rail Installation

Hold Down Rail amapangidwa ndi zinthu za HDPE.Kuyika kwa Hold Down Rail pa C shape rabbet part kuyenera kutsata chimango chachitsulo pambali ya conveyor, kutsatira motsatira radian ndikuyiyika, kuti mumalize kuyika.Pamalo ogwiritsira ntchito kutentha kochepa, imapezeka kuti igwiritse ntchito chowotcha cha gasi kapena chotenthetsera mpweya wamagetsi kuti itenthe mpaka 100 ~ 120 ℃ ndikuipinda moyenerera kuti igwirizane ndi kuyika kofunikira.

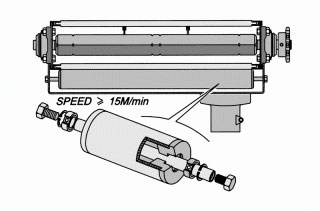

Liwiro Lantchito

Lambayo adzakhala ndi mkhalidwe wowunjikana mobwerezabwereza, ndipo zimapangitsa lamba kuyima kaye ndi kunjenjemera.Choncho, pamene liwiro ntchito ndi apamwamba kuposa 20M pa mphindi, kutengera mpira kubala odzigudubuza m'malo kugwira pansi njanji mu malo kubwerera njira kuthetsa vutolo.

Interval Limitation of Return Way Roller

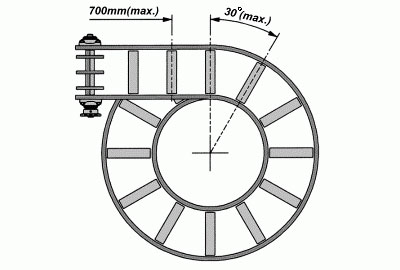

Mukatembenuza lamba wa conveyor gwiritsani ntchito zodzigudubuza zonyamula mpira kuti zithandizire njira yobwerera, nthawi yapakati pa odzigudubuza pagawo lowongoka iyenera kukhala yaying'ono kuposa 650mm.Mbali yophatikizidwa pagawo lotembenuzidwa siipitirira madigiri 30 kapena kutalika kwa poto wakunja sikuposa 600mm, avareji ya ngodya yophatikizidwa.Idzakhala ndi malo okhudzana ndi ambiri pamene odzigudubuza amathandizira lamba.Ngati utali wa mapindikidwe akunja ndi wopitilira 600 mm wa nthawi yodzigudubuza, iyenera kukhazikitsa kalozera wazithunzi (UHMW) kuti atsimikizire kukhazikika kwa njira yobwerera.

Zolemba za Belt Width

Zogulitsa zikakwera panjira yokhotakhota, zimatsata kayendedwe ka conveyor kupita patsogolo.Zamgulu sazungulira padziko lamba chifukwa liniya liwiro la conveyor lamba ali konsati zoyenda pa zonyamula.Chifukwa chake, popanga dongosolo la lamba wotumizira, lamba m'lifupi liyenera kukhala lalikulu kuposa m'lifupi mwake mwazonyamula.